Being avid Powersports enthusiasts and DIY mechanics, like many of you, we had set out to change our own tires on our personal vehicles. We like wrenching on our machines, knowing that the work is done right. When it came to swapping tires on our ATV’s, we quickly learned that it was quite a different job than changing our oil. We tried all of the DIY tricks: 2×12’s, bottle jacks, you name it..the beads wouldn’t budge! We bought cheap bead breakers, only to find that they didn’t work either, and we actually managed to ruin an expensive aluminum racing rim in the process!

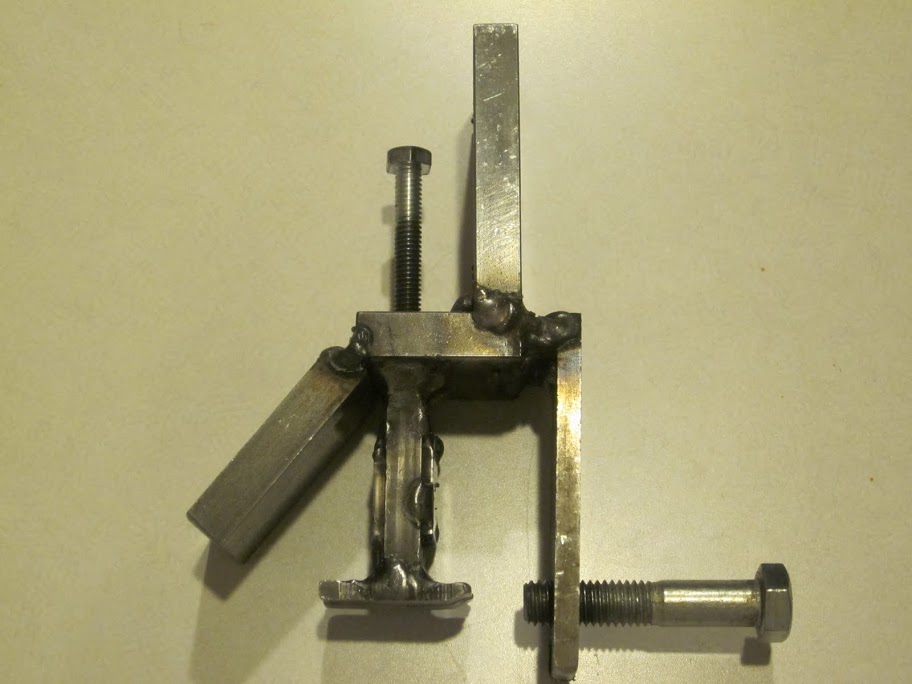

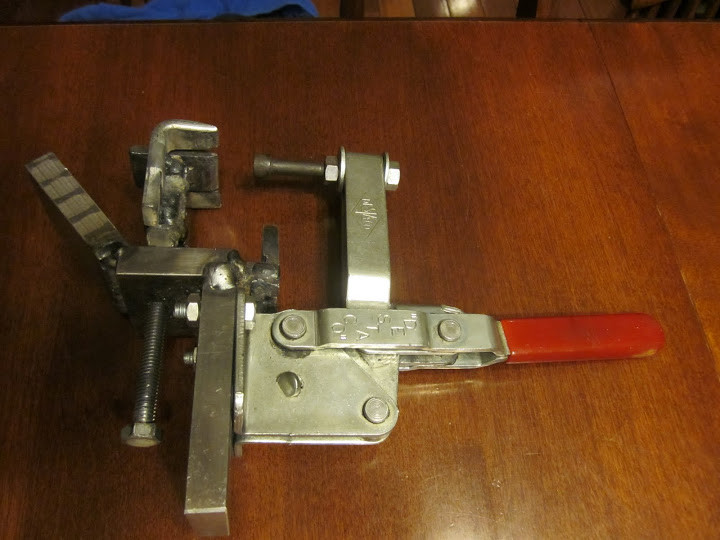

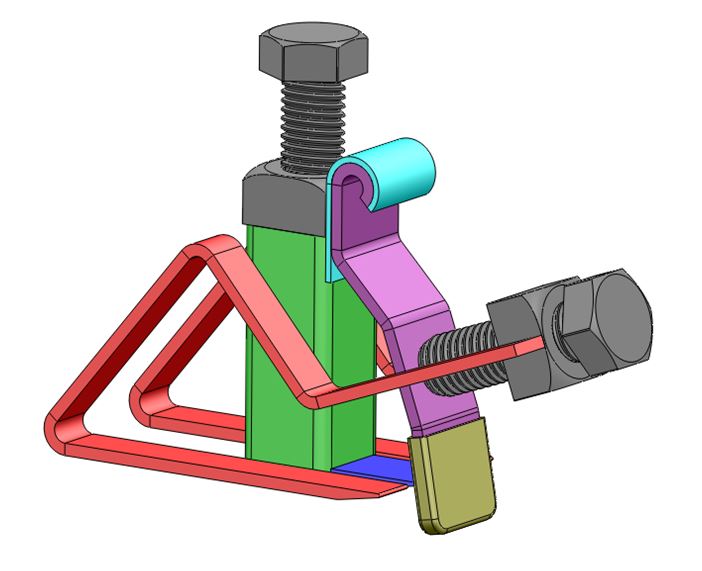

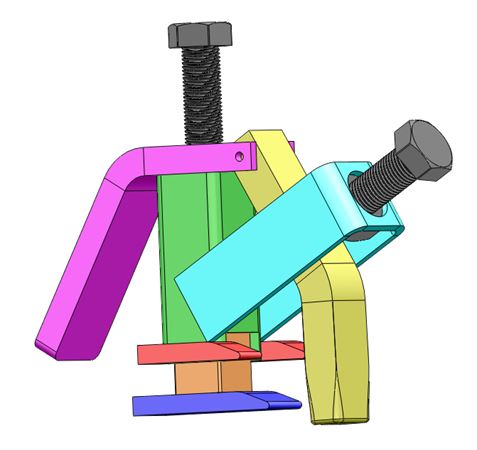

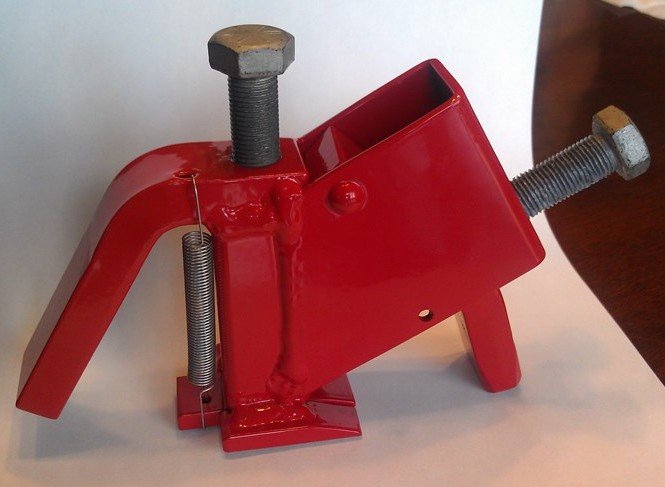

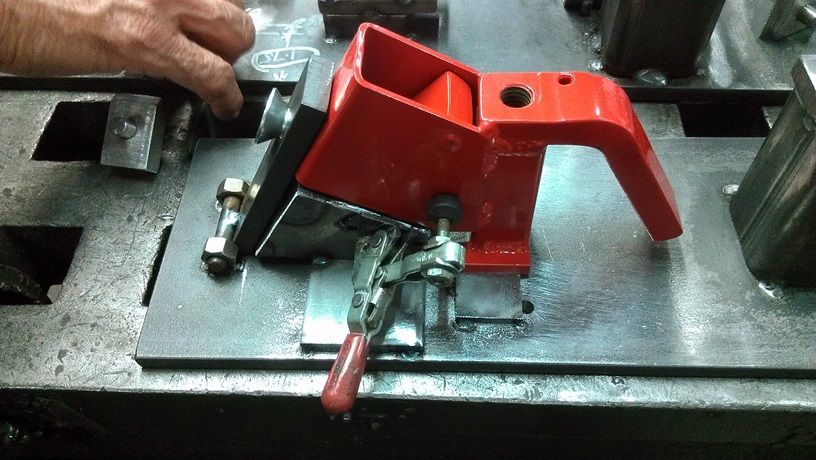

So we put our heads together, and tried to come up with a better way to change our own tires. Instead of suffering with bloody knuckles or ridiculous dealership service charges, we endeavored to design and build our own manual tire bead breaker that does the job properly and efficiently, every time. It started out for just our own personal use, but soon our riding buddies kept asking to use our home-made ATV bead breaker…again and again. So we decided to take a chance, refine the design, start a company and manufacture our tool to give all of our fellow riders a helping hand. After all, you need the right tools to do a job, and there is no better manual tire bead breaker than the BeadBuster.