WATCH THE VIDEOS

DETAILED INSTRUCTIONS, TIPS & TRICKS

PROFESSIONAL FEATURES:

- HARDENED ALLOY STEEL CONSTRUCTION

- GRADE-8 BOLTS

- EXTENDED 1” FEMALE RAM THREAD

- 3-YEAR WARRANTY

The BeadBuster XB-450i was designed to work on most tires LESS THAN 32” OD, including:

1. Remove the valve core to completely release air pressure from tire.

2. Start with the ‘shallow’ side nearest the drop center…this is usually the outside face of the wheel. Apply BeadBuster Tire Mount Lube (or other lubricant, like soapy water) to the bead. Push down on the sidewall to ensure that soapy water flows in between the rim and tire. Changing tires is essentially a battle against friction. Tire mount lube reduces the friction and makes the job much easier.

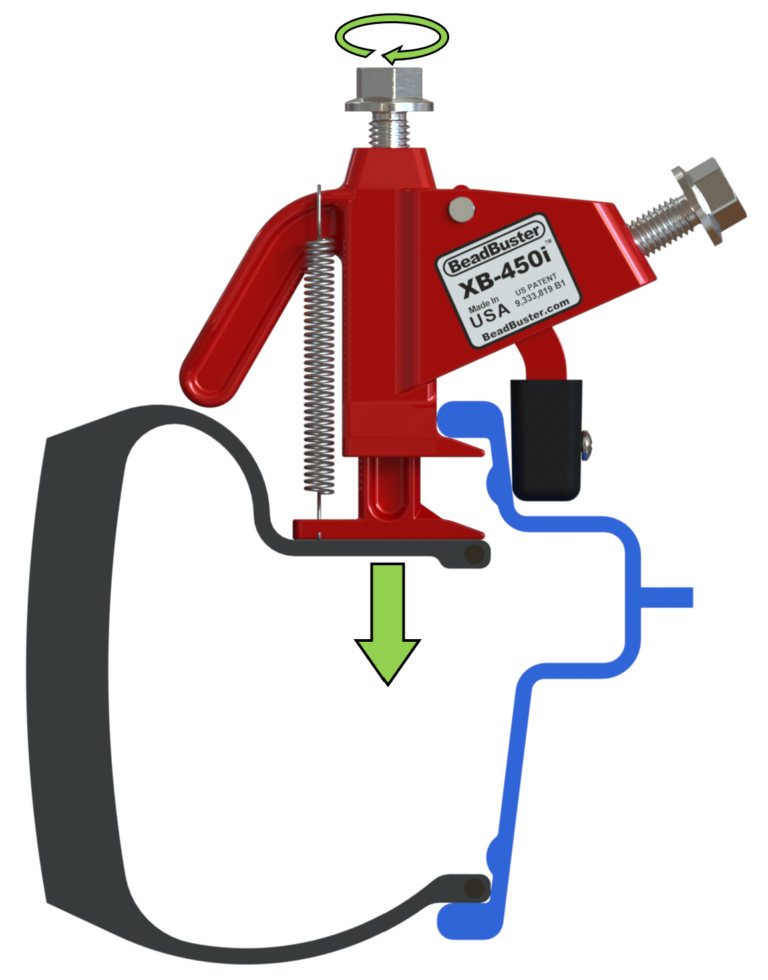

These images are intended to give you a reference of what the tire and wheel look like when sectioned through the middle.

.

.

3. Press the feet of BeadBuster XB-450i in between the lip of the rim and the tire bead. Use the handle of the BeadBuster to aid in getting the feet positioned and applying downforce on the tire sidewall. The tire mount lube helps it slide in. Pressing the feet down onto the sidewall 1st helps create a small gap for the feet to enter. Make sure the feet are started in the tire-rim gap before advancing the clamp bolt. DO NOT USE a hammer to force the tool into place.

4. Use a 3/4” socket or wrench to tighten the clamp bolt to pull the feet all the way in and align the tool. You can use an impact wrench, ratchet, drill or hand wrench. A typical ATV tire requires 7-9 ft-lbs (112-144 in-lbs) of torque to get the feet in. Use caution with a 1/2″ impact wrench to not over-torque the bolts, as you could damage the bead breaker, tire and wheel.

>> IMPORTANT NOTE <<

The BeadBuster MUST BE ROUGHLY PERPENDICULAR to the face of the rim before breaking the bead. If the Beadbuster is not properly clamped and aligned with the rim, the Ram Foot may engage the Bead Retainer possibly damage the tool, but more likely damage your rim while breaking the bead!

The most important factor when using the BeadBuster is having proper alignment with the rim. The Tool Body must be drawn in within 1/8” of the edge of the rim, ideally touching it. Some stubborn tires result in the tool being out of alignment once contact is made. If this is the case, after you get the feet fully inserted, back off of the clamp bolt until the BeadBuster XB-450i is realigned perpendicular to the rim, but still fully inserted.

● If Over-Clamped and the tool is leaned in toward the rim, the Ram Foot could gouge the bead retainer causing damage to both the tool and rim. This is the most common problem users have with using the BeadBuster.

● If Under-Clamped and leaned away from the rim, the Ram Foot could slide down the sidewall and possibly damage the tire.

-

If the tool is leaned backward (Over Clamped), the Ram Foot will engage the Bead Retainer and damage to the tool and rim is likely.

-

The BeadBuster must be aligned roughly perpendicular to the face of the rim before running down the Ram Foot.

-

If the tool is leaned forward or not pulled in far enough (Under Clamped) , the Ram Foot may miss the Bead Bundle entirely and puncture the side wall.

5. Use a 3/4” socket or wrench to run down the Ram Bolt until the tire bead has been pushed past the bead retainer on the rim. Again, an impact wrench can be used, but be cautious with a 1/2″ impact so that you don’t over-torque the bolt, which could strip the threads.

Depending on the age of the tire and condition of the rim, the bead may partially return to the seated position when the Ram Foot is retracted. If this happens, insert a small block of wood or plastic between the tire and rim to prevent it from re-seating.

The bead retainer on the rim will be visible after pushing the tire bead past it. It is recommended to visually inspect the gap during operation to ensure the Ram Foot does not catch on it.

There is a tendency to want eagerly to push the bead down all the way in one spot, however the BeadBuster XB-450i only has 1.438″ of travel. Observe when the Ram Bolt has bottomed out on the top of the tool body, and make sure not to tighten beyond that point, or you can strip the threads with a powerful wrench.

6. Loosen the Ram Bolt and Clamp Bolt. If you cannot break the remainder of the tire bead loose by hand, move the BeadBuster XB-450i to another location on the rim, adjacent to where the bead is broken. Repeat the process at the next spot. On very old and stubborn tires, you may need to use the tool 3-4 times around the rim.

Some wheel types (such as Sprint Cars) have a very tight interference between the Tire and Wheel, and the force required to break the bead is very high. The reason is because when you start to break the bead on one side of the wheel, it is putting the steel cord (Bead Bundle) in hoop tension, and you are essentially stretching it.

For these cases, even some very stubborn ATV wheels, to prevent bending damaging the ram foot or damaging the tire (if you intend to re-use it) you need to avoid trying to use the full travel of the Ram Foot. Instead, you need to take more frequent, smaller ‘bites’ around the rim. We call it the “Inch-Worm Technique”. Break the bead in one spot, extending the Ram only about 3/4″-1″, and then work your way around, every few inches…this will minimize how much you have to stretch the Bead Bundle. This technique is necessary only on the most stubborn wheels, and sometimes on wide ATV wheels, on the side opposite of the drop center.

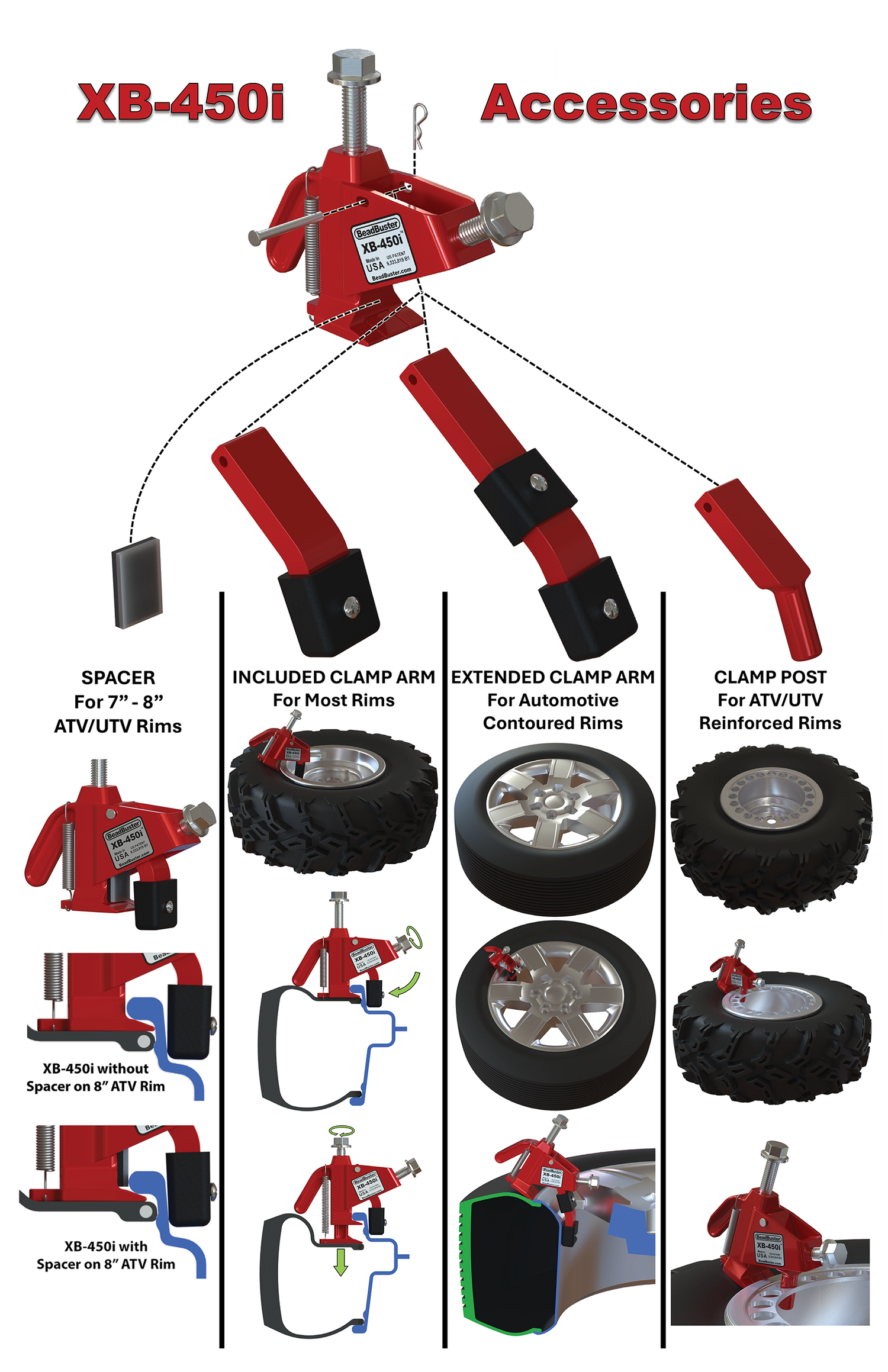

XB-450i ACCESSORIES FOR SPECIAL APPLICATIONS

The BeadBuster XB-450i comes with a Standard Clamp Arm. There are some special applications that require an accessory clamp arm to properly interface with the wheel.

-

SPACER FOR 7"-8" ATV/UTV RIMS

BUYThe operating principle of the BeadBuster relies on the Ram Foot reaching as far as possible underneath the lip of the rim so that it covers the steel cord (Bead Bundle), but does not contact the Bead Seat or hit the Bead Retainer when the Ram Foot pushes down.

The minimum Rim Lip Depth (d) that the XB-450i can be used on is 0.585”. Smaller rim lip profiles (such as 7”-8” ATV wheels, ie. 3-Wheelers and Mini-Quads) require

the accessory spacer. -

EXTENDED CLAMP ARM FOR AUTOMOTIVE CONTOURED RIMS (BB1X-CAE)

BUYSome Automotive wheels have a clamping surface that is angled or curved. The standard Clamp Arm can’t get a grip on these wheels, but the Extended Clamp Arm will reach down deeper into the rim and grip it properly where it is flat.

-

CLAMP POST FOR ATV/UTV REINFORCED RIMS (BB1X-CAP)

BUYReinforced ATV rims (AKA “Rock Rims”) have one or both rim lips bolstered with a reinforcing rim stiffener. The clamp post is needed with these rims to reach through the ring holes to make contact with the inside clamping surface of the rim.